You commonly see this expression, in magazines and automotive sites, or in releases and manuals made by manufacturers. A lot of people know that it’s something important, but they can’t explain what it’s about – even know talk about how the lack of torsional rigidity can affect the behaviour of the car. So, how about we she a light on this? Pull up a chair and pour yourself a cold beer!

Table of Contents

What is Torsional Rigidity?

The car is a structure supported on the ground by four points (ignore the Morgan 3 Wheeler for a moment): the tires. Connecting them to the body, we have the suspension assembly: axle sleeves, arms (or trays), springs, shock absorbers, bushings, etc.

Turns, obstacles (spines, holes, etc.), braking and acceleration cause weight transfer that convert to vertical forces. They are picked up by the fires and wheels, transmitted to the suspension and finally passed to the body by the attachment points of the suspension. Each component absorbs some of this energy, specially the more flexible ones, such as tires, suspension bushes, springs and shock absorbers.

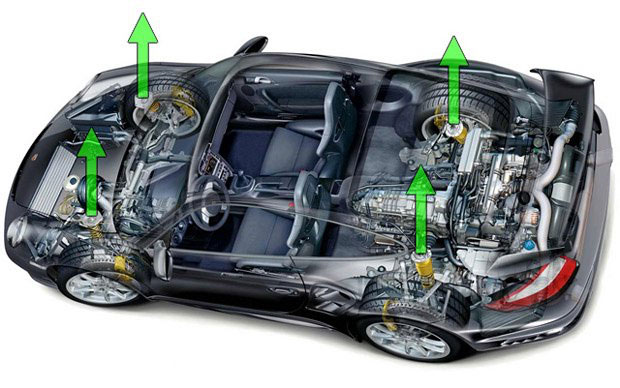

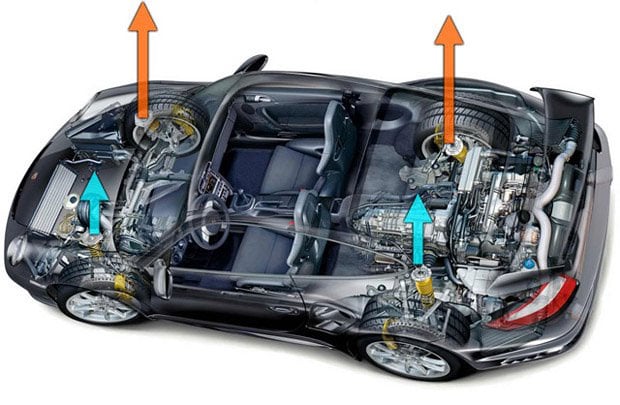

In the image below, the car is stopped. There is no additional force acting other than the weight of the car itself. For this example, ignore the typical Porsche 911 weight distribution.

Now, if he is making a left turn at high speed (picture below), the weight is transferred to the right. The tires on the right side receive much more cargo, it is passed through the suspension and transmitted to the body. Notice how the (hypothetical) vectors of force become unequal: it is this difference of torque applied in the bodywork that causes the torsion. And you see that the example below is not even the most extreme – on the contrary, it represents the ideal dynamic situation: a constant curve. If there is combined braking or acceleration in the curve, each of the four vectors would have a size – after all, braking and accelerating cause longitudinal weight transfers, which would become diagonal in these circumstances.

For you to understand the twist easily, grab a sheet of sulfite and glue four fingers of it with crepe tape, one on each vertex, simulating the points of support of the suspension. Now, force the paper up with these fingers, making multiple combinations: only one, in pairs, crossed, only one side, only another. You will see that the freight sheet in several ways. It stands to reason that the body does not bend this way, but the force acts in the same way.

But it can get worse. Much worse. The example below is extreme: a test with crossed and unequal points of support. The right rear tire is on the ground, the left is on its way up the ramp. On the front axle, the right side is completely over the ramp and the left is in the air, without any support. Argh! The twist is completely visible: compare the rear window’s baseline with the top of the bucket lid!

Although on a smaller scale, the cars are subjected to the tensions of this type every day: that parking ramp that we climb in curve, ditches, spines, holes, craters, abysses, wormholes of Brazilian asphalt. In fact, cross-crossing obstacles cause greater structural stress, but cars are designed to deal with this without any problem: it is elastic deformation, back and forth, without loss of material properties.

In the example above, the left pickup has minor torsional stiffness. In the street, this tends to cause noises and creaks from the movement of the body elements and, in extreme cases, can crack the windshield and make it difficult to open and close the doors. On the track, lap times go up there because a twisting structure causes changes in suspension geometry, which does not work as it should. The detailed explanation of this last part is at the end of this post.

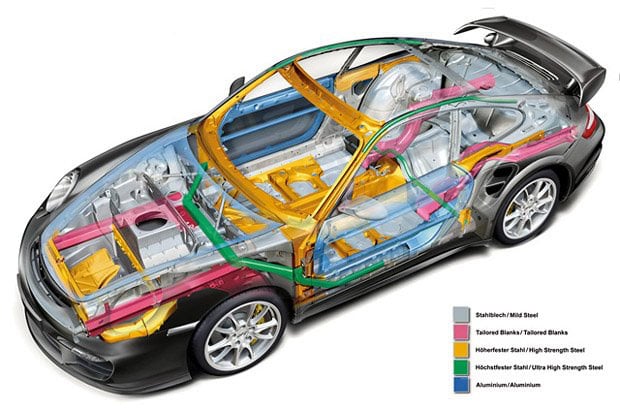

Important detail: we can not confuse rigidity to the torsion with capacity to absorb impact in accidents. First, a strike is a force exerted mostly horizontally, while the stresses that cause the twists are vertical. The structure of an automobile is extremely complex, involving multiple materials, with multiple thicknesses and profile designs. Every car has a programmed deformation zone on the front, rear and sides – and this does not affect practically any torsional stiffness, which “really matters” structure is almost all between the axles. It is like comparing skin and muscles to bones: the chubby has bones as hard as a skinny one.

How is the torsion measured?

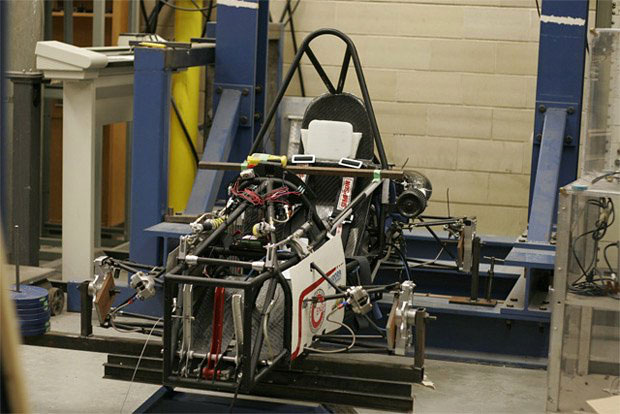

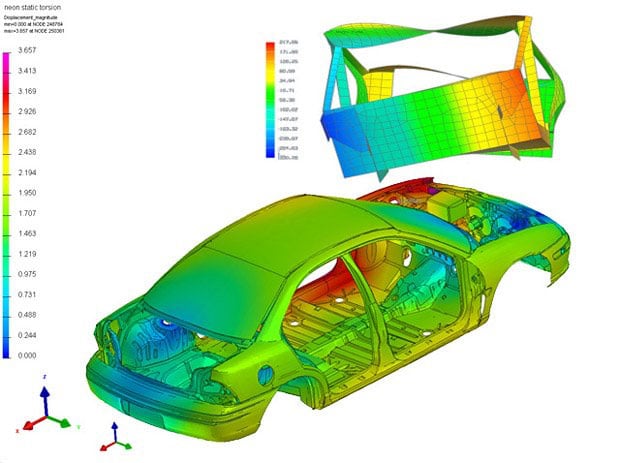

The unit used by the factories for the structural torsion is Newton-meter / degree, that is, a torque is applied and the bending is measured in degrees. The torque is applied to the shaft ends, simulating the force passed through the wheels to the suspension assembly. And how is this done? Well, back in the day, this was done literally, with a perfectly level table, whose jig fixed two or three points of the suspension and applied torque via the weight and lever system. In fact, this method is used even today by racing teams and smaller manufacturers – and more practical and inexpensive. In the photo below, we see in the cockpit the bar used to read the twist.

But most large factories today do everything via software – the same as running virtual crash tests. After all, the design of all components is already on the computer, with all the properties and thicknesses of the metals used, welding points, etc. However, as with dynamic tuning, the simulation does not dispense with practical tests.

If you want a homemade way of checking if your car is rigid monobloc or if it is a wet ice cream cone, simply climb on a high guide with only one of the tires – preferably so that the tire on the opposite diagonal stays in the air (you can do the same with easels). Try to open and close the doors. If you roll smoothly, congratulations, your car is thick-walled. If it is difficult to open, if it crashes strangely, or if some small boat-like cracks rolled in the sea, it is because the body has twisted a good bit. In critical cases, you will not be able to close the door.

Why are convertibles more sensitive?

The best demonstration is old (but gold): get a box of shoes with a lid. Put a hand on each diagonal and twist it. Now do the same on her with no cover. It is explained. Structurally speaking, what detracts from the convertibles are the lack of the center and rear columns and something that connects all the columns – the roof. Without this, all the stress-absorbing work is left with the floor, which receives a series of additional reinforcements (we’ll talk about them in the next part of this post) to deal with the extra stress.

And not only are convertibles: cars with longer wheel axles (think of a longer box), shorter struts (pictured below, painted green), with narrower columns, with few soldering points on the plates that form the monobloc , with many flat plates on the floor (folds and omega-shaped profiles increase resistance), without localized reinforcements, all this reduces torsional stiffness.

Okay, okay, I get it. And how does the torsion affect the behavior of the car?

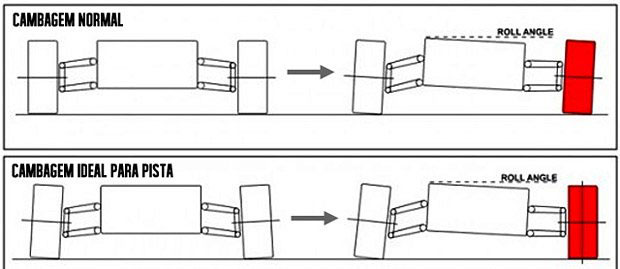

Well, to explain this stop we need to go in parts and explain other concepts before. First, did you know that the geometry of the suspension – particularly the suspension – does not remain fixed when the suspension moves? Looking at the car from the front, from the minimum stroke (compressed) to the maximum (stretched) of the suspension, the tire describes an arch at this displacement. See the suspension on the right side of the image below.

This arc is called a bending curve – it varies in each car, according to the length and angle formed by the suspension arms.

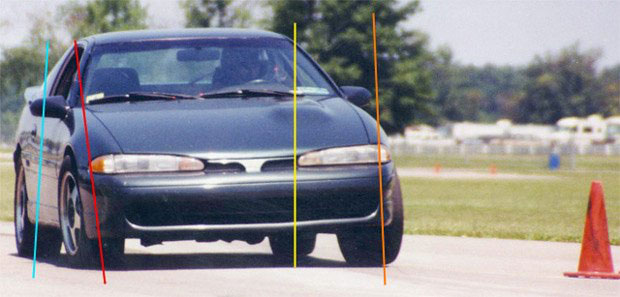

Now, let’s compose the zone: as we saw above, the suspension of each corner receives a different vertical force. That is, in the curves, each wheel assumes a value of change. See the photo below. It seems a little frightening and chaotic, but the geometry of the suspensions is calculated together: the relationship between the change of the here, there and here is something predicted and scaled.

With that, you can understand why race cars have the negative static wobble – that is, with the top of the tires tilted inwards. If the guy got the perfect calibration, when the body tilts in the corners, the change of the wheel with more support will assume value near zero (in fact, little negative thing), using the maximum of the tire and achieving more grip.

At the top of the picture above, we have a car with a static wobble that is zeroed, like in a common car: in curves made in the limit, it is seen that the tendency is for the cambian to stay positive in fast turns; which results in forces contrary to those desired for adhesion. At the bottom, we see how the negative shift behaves with the body roll.

When the car’s structure is not rigid enough and it twists too much, it picks up the four paragraphs above, kneads and throws it in the trash. The reason is simple: body twisting enters as an unpredictable variable in suspension set geometry, causing shifting values that are not conversant and do not match the design. Imagine four balancers on the vertices of a square table – but switch the wooden table to another with a very elastic rubber. The dynamics become chaotic, unpredictable, and the car becomes unable to fully exploit the tires.

Structural stiffness is vital in sports and preparation: the more tight the tires are, the more rigid the suspension, the greater and more direct the force transmitted to the body. This applies to both track use and everyday situations, as you can see in the video above. Monoblock sports car suffers – a lot.

And how do you get rigid to twist in a car? It’s the subject of our next post.